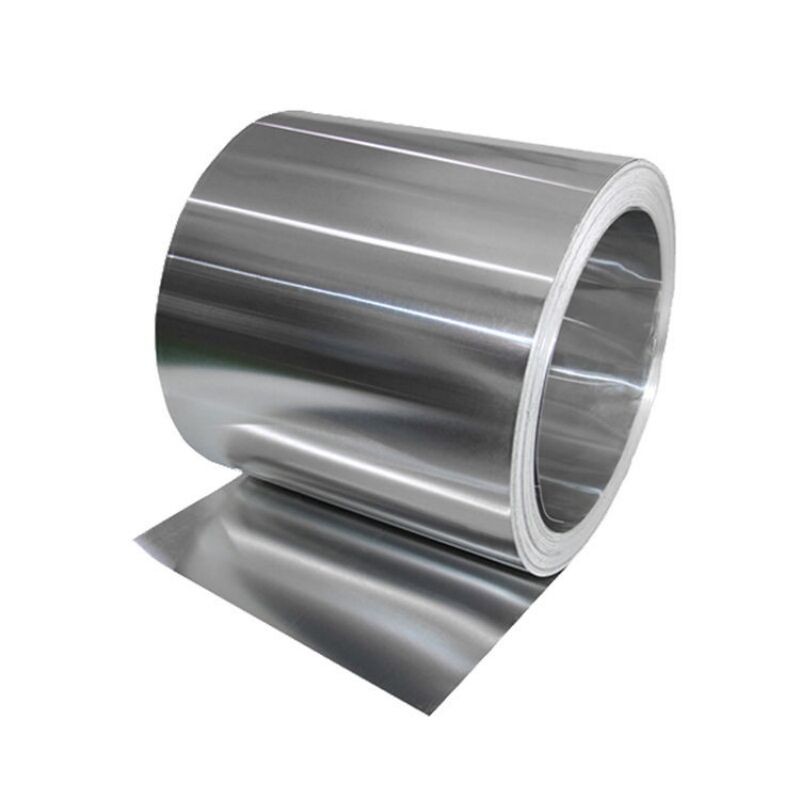

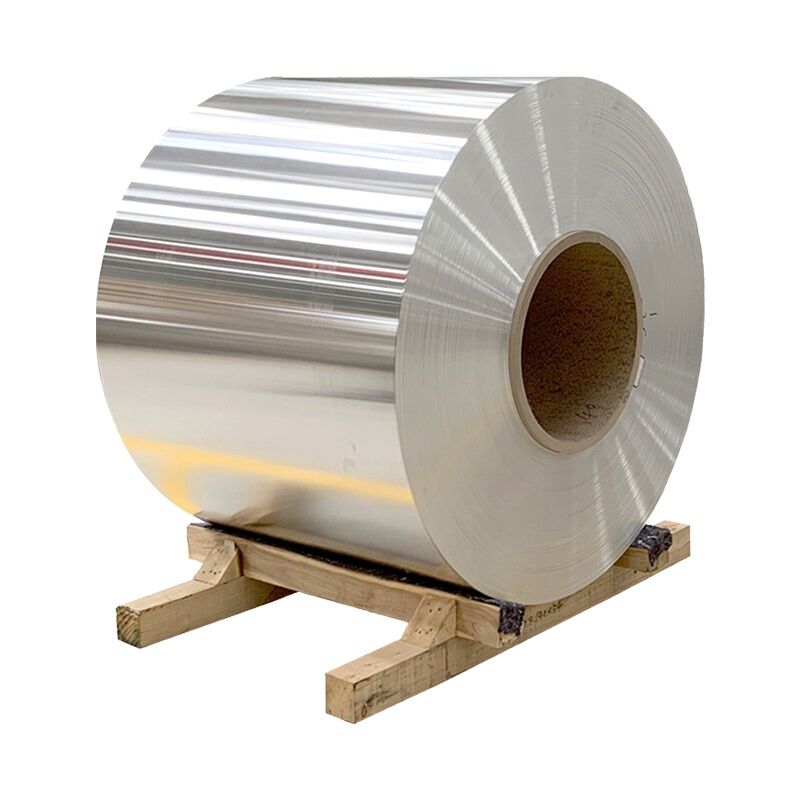

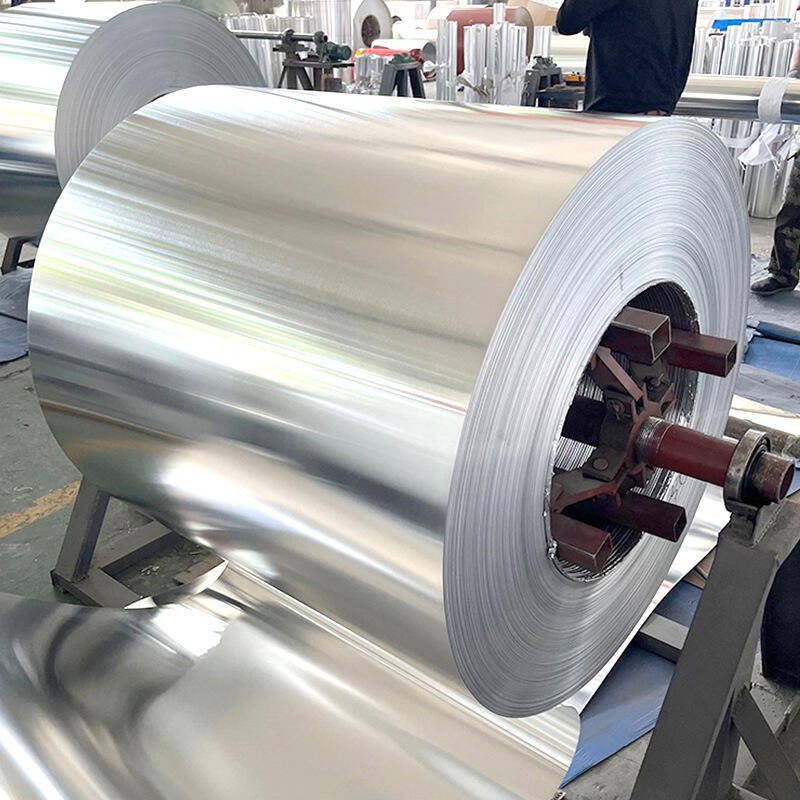

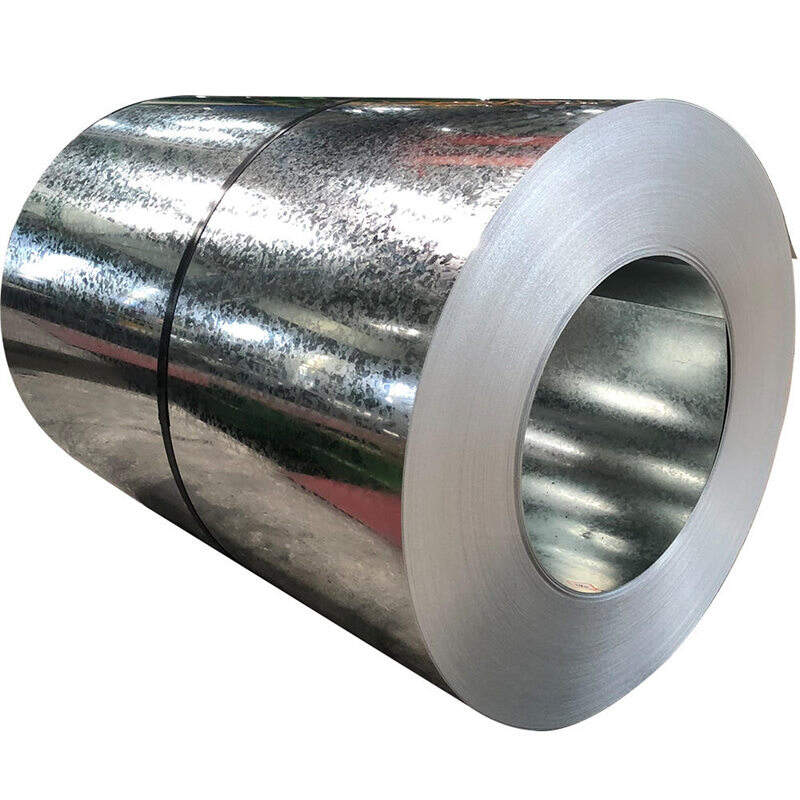

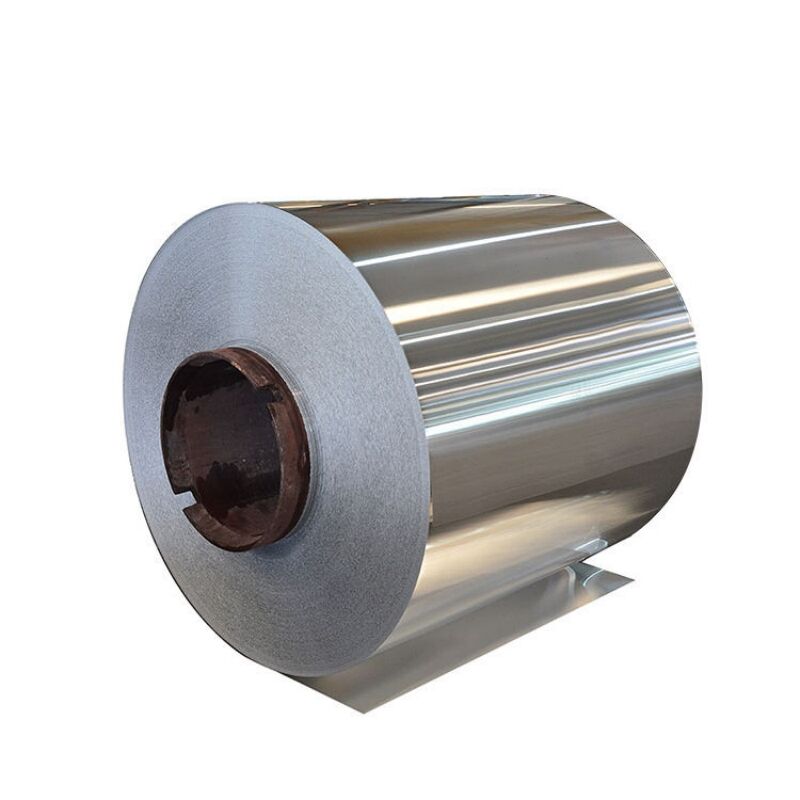

Aluminum Coil 0.2-1.5mm Thickness 1050 1060 1100 6063 6061 5052 4047 7075 Aluminum Roll Coil

| Minimum Order Quantity: | 1 Ton |

| Packaging Details: | Standard sea freight packaging |

| Delivery Time: | Within 7 days |

| Payment Terms: | T/T |

| Supply Ability: | 1000 tons per month |

- Overview

- Inquiry

- Related Products

Description

When exposed to the atmosphere or any other oxidizing agent, aluminum forms a thin, hard film layer of aluminum oxide. This oxide layer prevents further oxidation, making aluminum corrosion-resistant.

Unlike steel coils, coils made of aluminum are ideal for applications where parts will be exposed to moist environments.

Competitive Advantage

1. Fast delivery time

2. Best price

3. Strong product supply chain

4. Convenient shipping conditions

Quick Detail

Aluminum coil refers to sheets of flattened aluminum that have been rolled (or coiled), with the width of the sheet being much greater than its thickness.

Applications

| Thickness | 3 mm – 10 mm |

| Width | 20 mm – 1500 mm |

| Tempers | -F , -H, -O, -T |

| Finishes | Original |

| Place of Origin: | China |

| Brand Name: | DYD |

| Model Number: | 510002575 |

| Certification: | ISO ASTM JIS |

Applications

The Automotive SectorAluminum coil is frequently utilized in the automotive sector. For example, aluminum coils are used to create the components used to build cars and trucks. This is because these vehicles need parts that are durable, strong but comparatively light, and resistant to corrosion. After all, these machines will be used frequently, be required to provide both occupant safety and maximum gas mileage, and be required to withstand the various weather conditions one may encounter when driving them. Therefore, engine parts, air conditioners, radiators, wheel hubs, automobile doors, and many more components of most vehicles are made using aluminum coil.

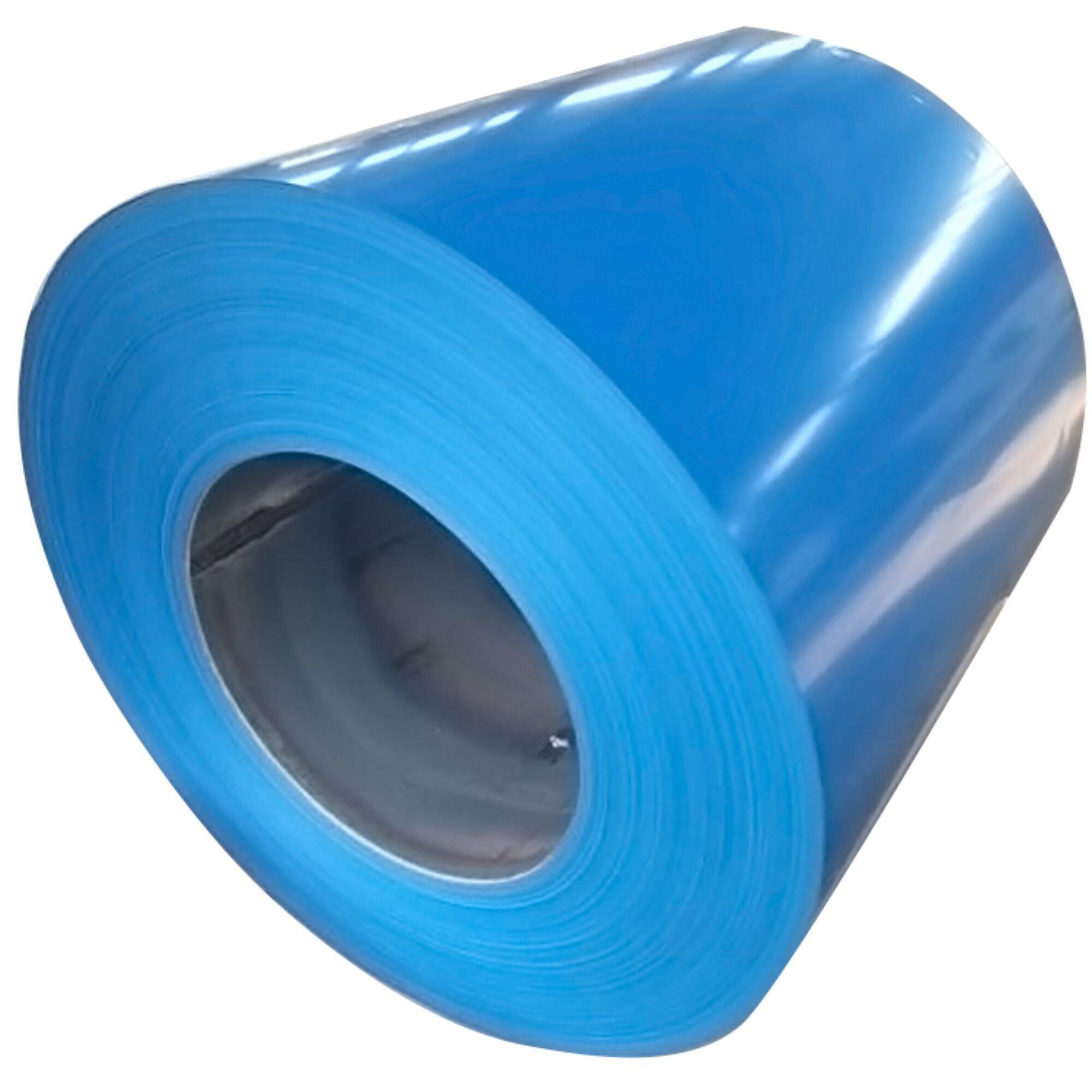

Protective Covering for Exposed Wooden Home Trim

A trim coil is a thin sheet of aluminum normally coated with polyester and is used to cover exposed wood trim on your home. This trim coil safeguards the underlying wood by preventing heat and moisture from destroying the trim's wood fibers.

Architectural Construction and DecorationAluminum coil will frequently be used for architectural ornamentation due to its resistance to corrosion, strength, and exceptional processing and welding performance. In addition, most construction projects use an aluminum coil to create structures, doors, windows, ceilings, curtain wall profiles, pressure plates, color coating sheets, etc., and surface decoration.

Components for Electronic AppliancesAlthough aluminum is not as electrically conductive as some other metals, numerous electronics frequently use aluminum coils. Since aluminum's resistance to corrosion ensures that wires will last a long time in hostile conditions, it is frequently used in wiring. Because of this, items containing electrical components, such as power cables and air conditioners, can endure the elements for a long time. Because of its corrosion resistance, most electronics can expect to have a reasonably long lifespan in general. Food ContainersAluminum's malleability, resistance to rust, and corrosion make it the material of choice for food cans. Aluminum is malleable, making it possible to produce cans in large quantities with no difficulty. In addition, aluminum can ensure that the food inside can stay fresh for a long time due to its resistance to rust and corrosion. In addition to cans, aluminum coils are used to make other containers like metal bottles, and their lid caps.

Advantages of Aluminum Coil:

1. Aluminum coil has a commercial benefit because it is far less expensive than other metals like copper.

2. Aluminum coil is a good electrical and thermal conductor. Because of these qualities, it is often found in appliances and wiring.

3. Aluminum coil is more flexible than steel.

4. Aluminum coil is relatively simple to make.

5. There are numerous alloys, widths, and temper criteria for coiled aluminum. Its surface finish can also be specified to order.

6. The fact that aluminum coils are recyclable is an additional benefit. Aluminum is expensive to extract from its ore, making recycled aluminum far more affordable than raw aluminum.

7. The advantages of aluminum for the environment are clear because of aluminum’s recyclability. As a result, coiled aluminum is a sustainable material.

8. Aluminum coil is perfect for many applications, ranging from its use as coating for decoration to its frequent use in automotive industries, due to its great corrosion-resistance and strength.

9. Aluminum coils are frequently utilized in the construction of most modes of transportation, including cars.

10. Aluminum coil is perfect for numerous industrial tasks thanks to its lightweight and sturdy structure.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

ET

ET

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

LA

LA

MN

MN

MY

MY

XH

XH