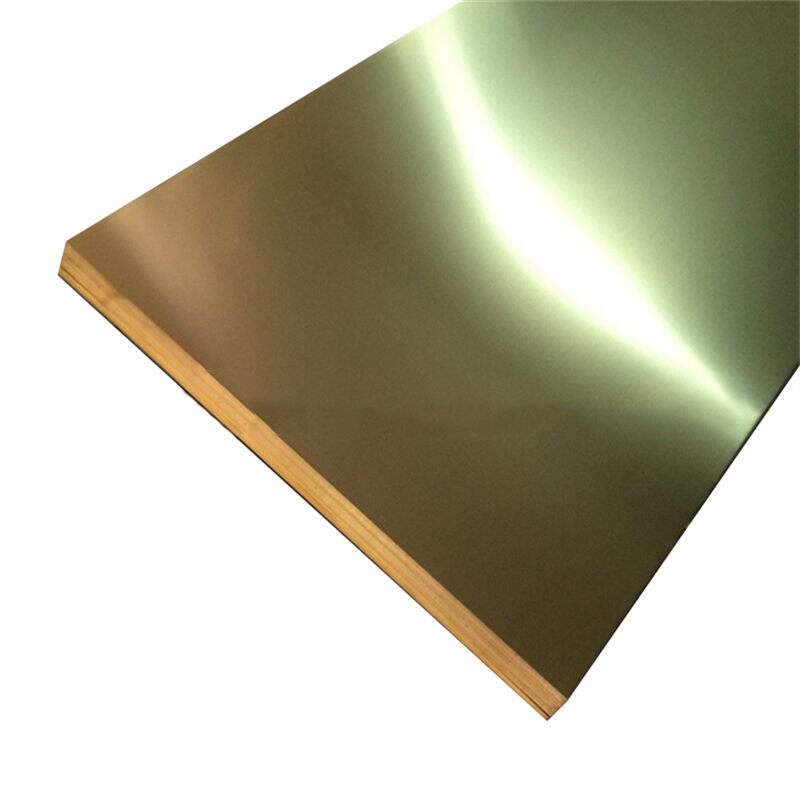

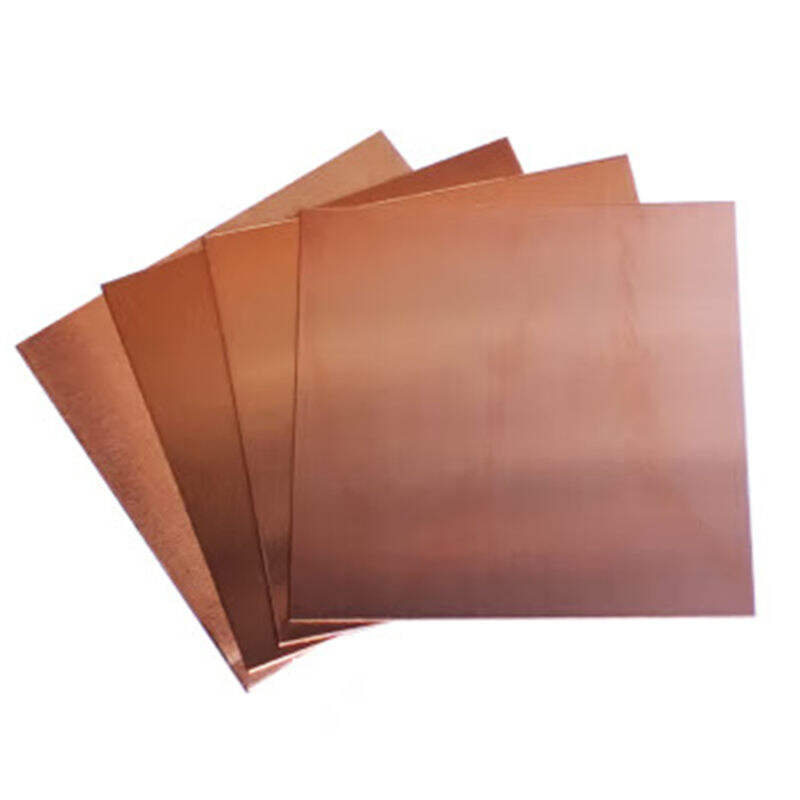

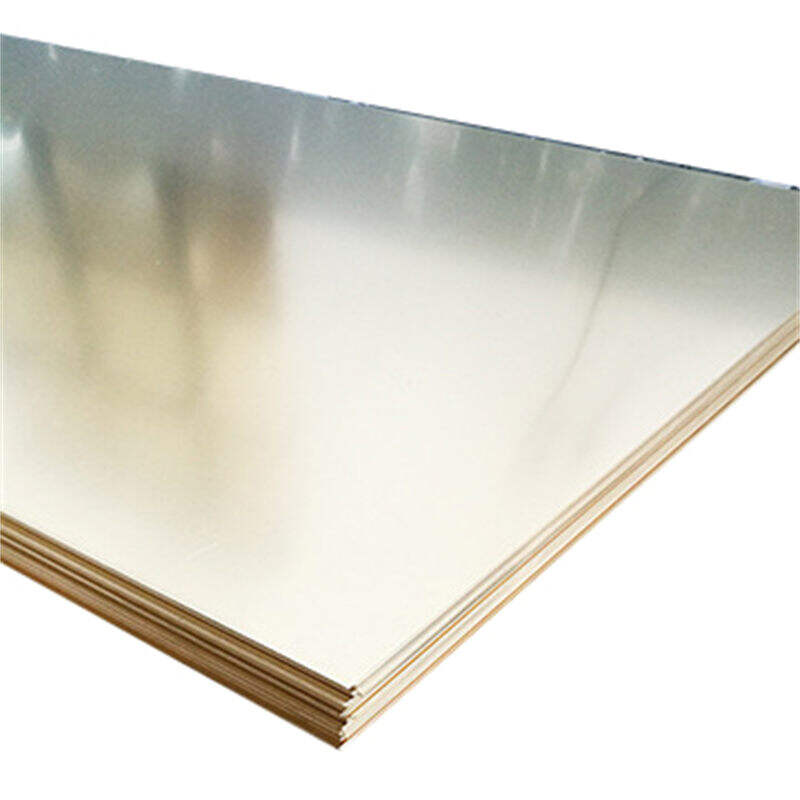

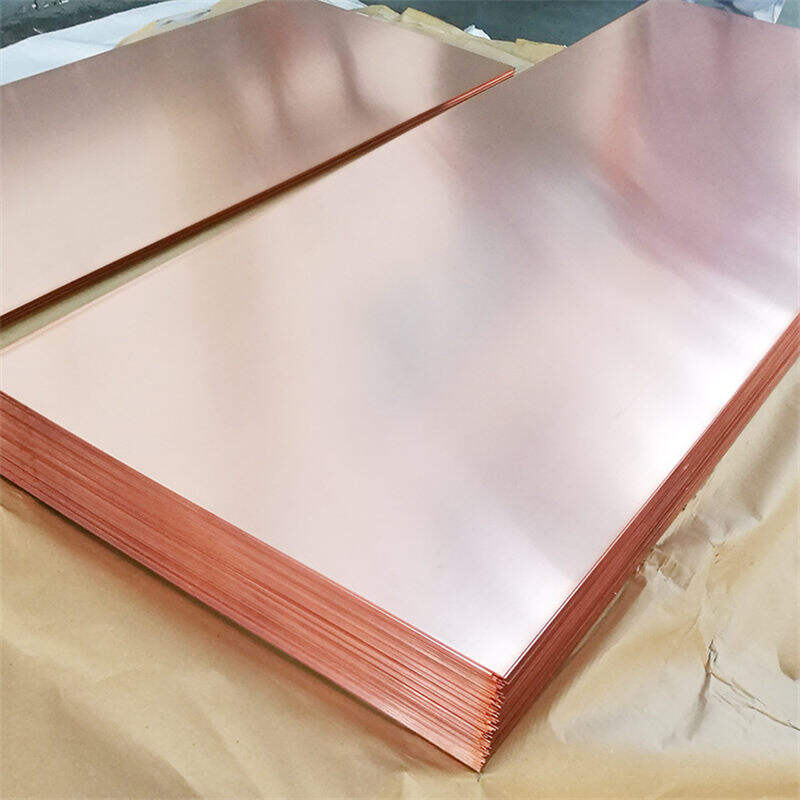

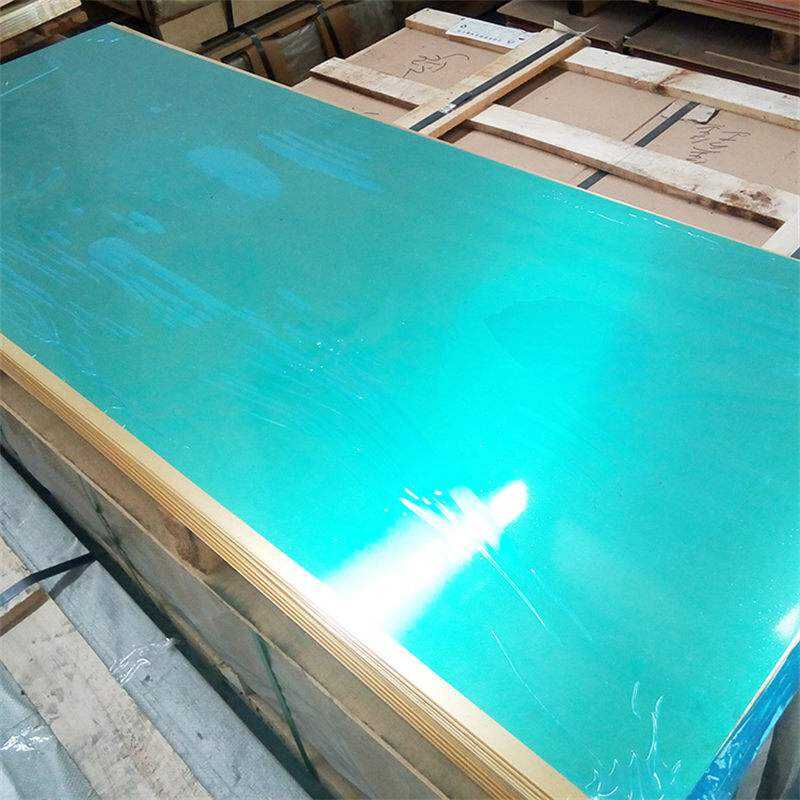

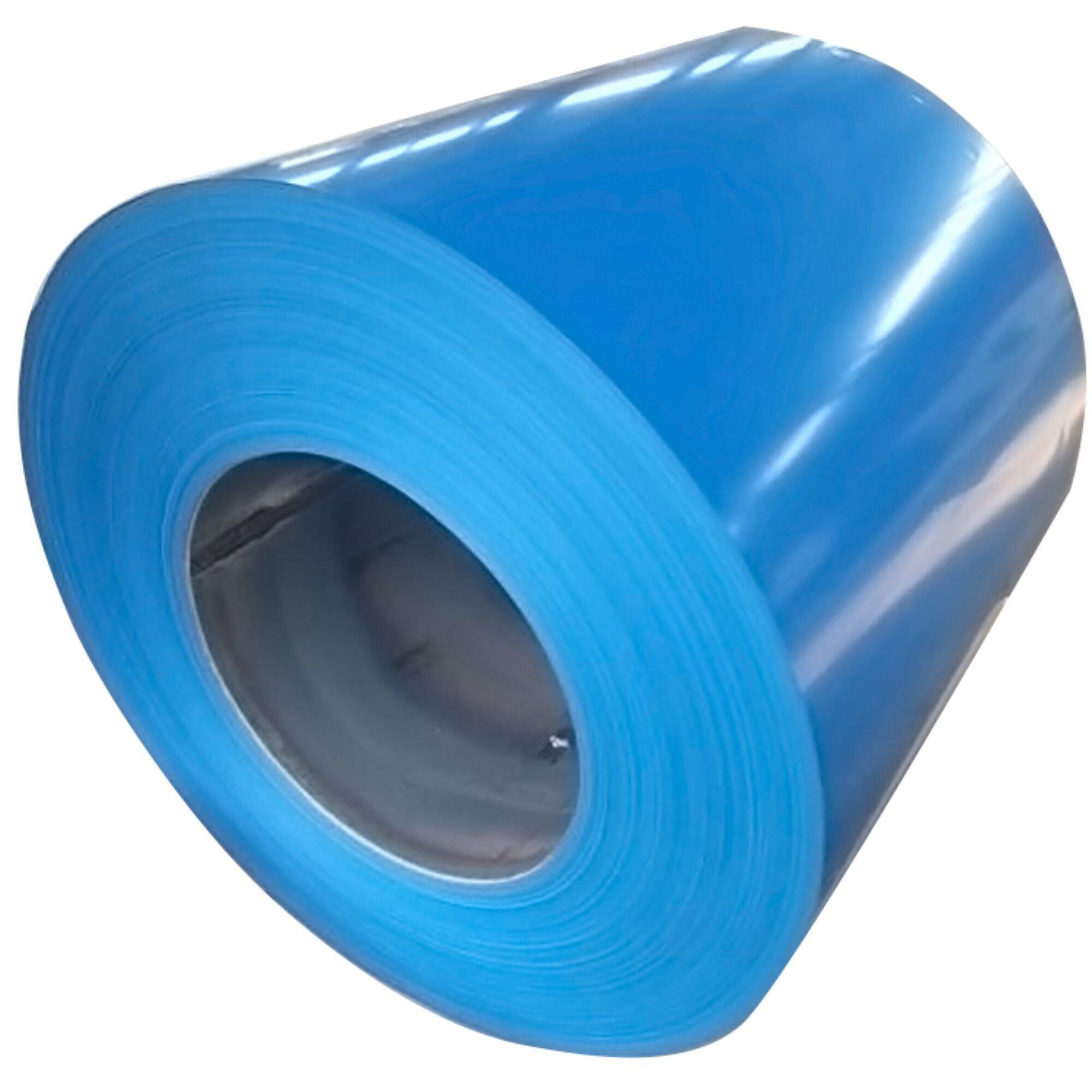

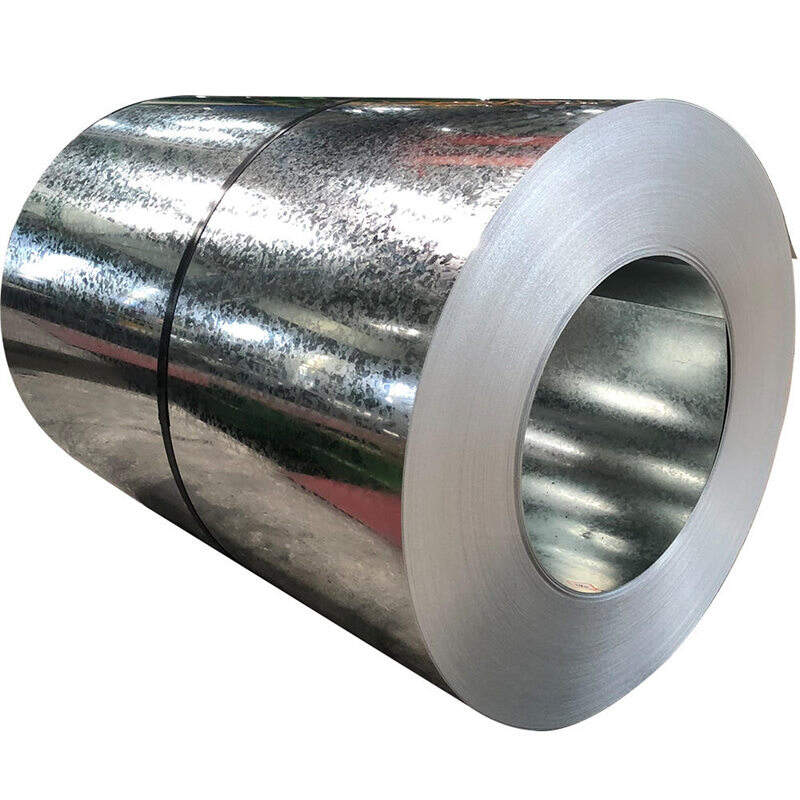

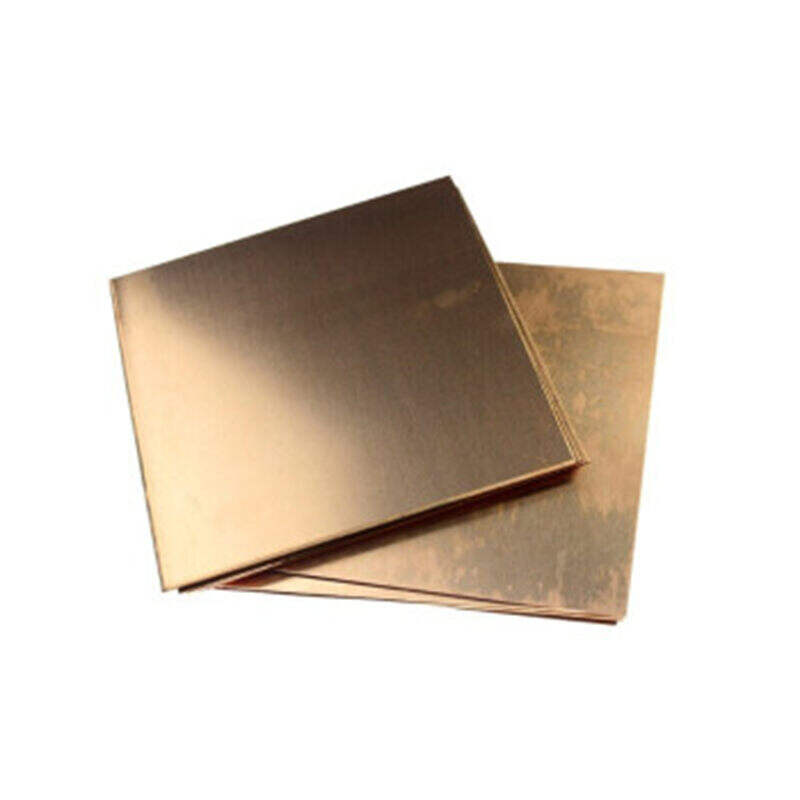

کیفیت بالا 99.99% C11000 سلف مسی / فولاد نازک مسی / برگ مسی برای الکترونیک

| محل اصل: | چین |

| گواهینامه: | ISO ASTM JIS |

| کمترین مقدار سفارش: | 500 کیلوگرم |

| قیمت: | 8199 دلار آمریکایی در هر تن |

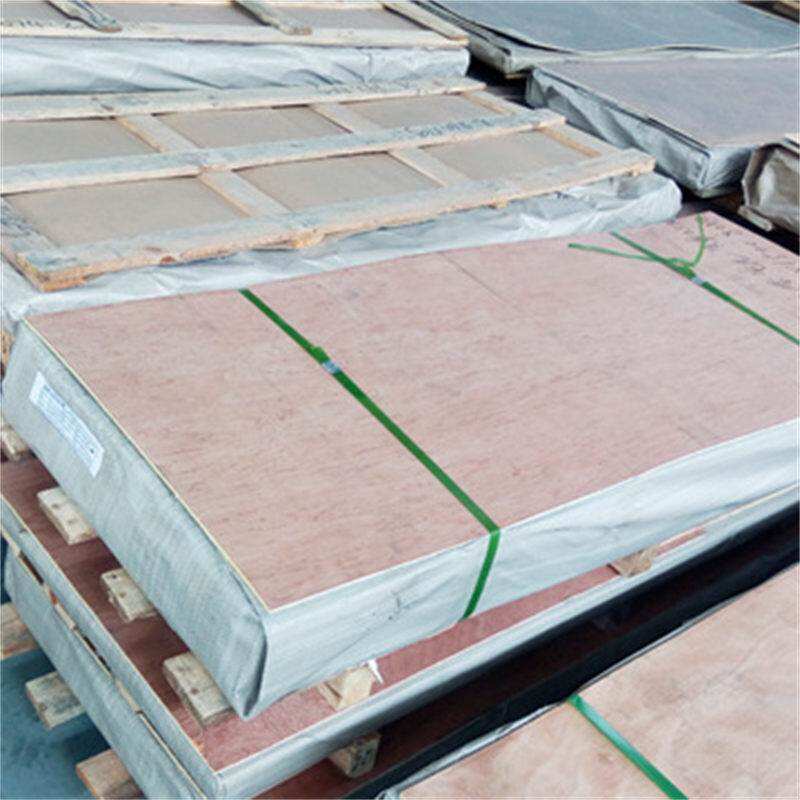

| جزئیات بستهبندی: | بسته بندی استاندارد حمل و نقل دریایی |

| زمان تحویل: | در مدت زمان 7 روز |

| شرایط پرداخت: | T/T |

| توانایی تأمین: | 500 تن در ماه |

- خلاصه

- استعلام

- محصولات مرتبط

توضیحات:

برگ مس یک فلز بسیار قابل تراشیدن و کاربرد دارد که رسانایی الکتریکی و حرارتی برجسته و مقاومت علیه خوردگی دارد. مس (Cu) یک فلز سرخ رنگ، بسیار شناور است که به گروه 11 جدول تناوبی تعلق دارد. مس میتواند در طبیعت به صورت آزاد و در حالت فلزی پیدا شود.

مشخصات:

استاندارد: ASTM B70 EN1652

گراد: T1,T2,C10100,C10200,C10300,C10400,C10500,C10700,C10800,

C10910,C10920,TP1,TP2,C10930,C11000,C11300,C11400,C11500,

C11600,C12000,C12200,C12300,TU1,TU2,C12500,C14200,C14420,

C14500,C14510,C14520,C14530,C17200,C19200,C21000,C23000,

C26000,C27000,C27400,C28000,C33000,C33200,C37000,C44300,

C44400,C44500,C60800,C63020,C65500,C68700,C70400,C70600,

C70620,C71000,C71500,C71520,C71640,C72200

| قطر | 3 میلیمتر - 100 میلیمتر |

| ضخامت | 0.5 میلیمتر – 50 میلیمتر |

| حالتها | H , 1/2H, O |

| پایانها | اصل |

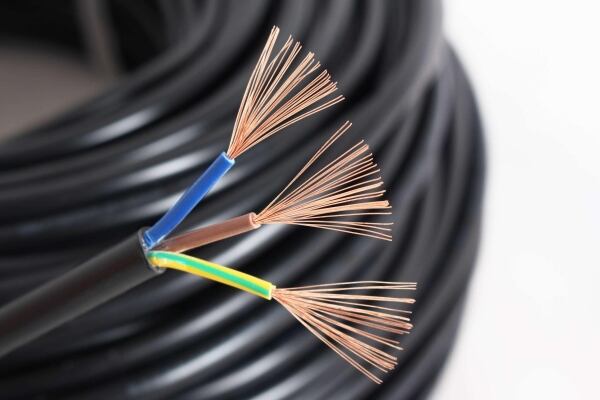

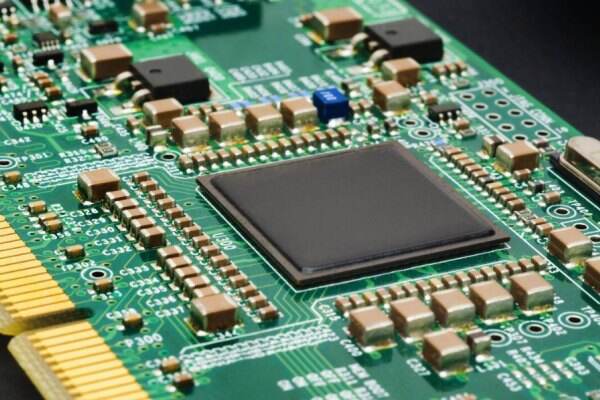

مس دارای بالاترین رتبه های导lectric و حرارتی بین تمام فلزات اصلی است. آلیاژهای مس به عنوان رساندهای برق منحصر به فرد هستند زیرا به خاطر رسانش بالا، نیروی ذاتی، قابلیت تراشیدگی و مقاومت در برابر خوردگی، مس برای استفاده در وصلیها و سایر کالاهای برقی/الکترونیکی مناسب است.

مس میتواند به علت نرمی، قابلیت تراشیدگی و ویژگیهای فوق العاده تراویجی آن برای اهداف معماری استفاده شود. مس با اضافه کردن عناصر دیگر تقویت میشود و آلیاژهای مس، مانند برنجها و برنزهای فسفری و نیکلهای مسی وجود دارد. ویژگیهای کششی در آلیاژهای مس دیده میشود که برخی آلیاژهای آلومینیوم را فراتر میرساند، به فولادهای صلب نزدیک میشود و دامنه وسیعی از کاربردها دارد. آلیاژهای مس میتوانند در کوچک کردن مولفههای الکترونیکی مفید باشند.

به خاطر مقاومت بی نظیر ضد خوردگی، مس و آلیاژهای آن در انواع محیطها و کاربردها به طور گسترده استفاده میشوند. لوازم و تزئینات معماری مسی، برنجی و برنزی همچنان در شرایط داخل و خارج از ساختمان خدمت میکنند. در هوا، آب غیر آلوده و اسیدهای غیر اکسیده کننده بدون گاز، آلیاژهای مس با نرخ بسیار کمی خوردگی مواجه میشوند. پس از هزاران سال در خاک، بسیاری از آثار آلیاژ مس به صورت تقریباً کامل کشف شدهاند. در مدت زمان ۲۰۰ سال، پوشش سقف مسی با نرخ کمتر از ۰٫۰۱۵ اینچ (۰٫۴ میلیمتر) خوردگی داشته است. آلیاژهای مس علیه طیف گستردهای از مواد شور، قلیایی و آلی مقاومت دارند.

مزیت رقابتی:

۱. زمان تحویل سریع

۲. قیمت بهترین

۳. زنجیره تأمین محصول قوی

۴. شرایط حمل و نقل مساعد

کاربرد:

ابزارهای جمعبندی برای درونکشی - قبل از درونکشی قطعات محصول، باید هندسه آنها با استفاده از ابزارهای جمعبندی برای تضمین کیفیت محصول نهایی ثابت شود. آلیاژهای مس مناسبترین گزینه برای این کاربرد هستند. اگر در حال ساخت تنظیم درونکشی خودتان هستید و سوال میکنید «مسافتهای مس من چقدر باید ضخیم باشد؟» راهنمایهای آنلاینی وجود دارد که میتوانید از آنها استفاده کنید. ریسمان زمیندهی - هر سیستم یا ماشینی که از برق استفاده میکند باید ریسمان زمیندهی داشته باشد تا اجزای اساسی و افراد را از آسیب ناشی از آسیب الکترواستاتیک (ESD) محافظت کند. لوازم آبرسانی - مس به دلیل مقاومت علیه فرسودگی، مواد مناسبی برای فلاشینگ است. حتی برای پوشش سقف کاملاً مناسب است، اما چون مس گران است، بسیاری از مردم آن را عملکردی نمیدانند. انتقال قدرت - بیشتر دندهها، چرخهای نوری، چرخهای بند و بوشهای مورد استفاده در سیستمهای انتقال قدرت از فلزات مقاوم و ضد فرسوده ساخته شدهاند. بسیاری از آلیاژهای مس معیارهای لازم را دارا میباشند. تعویض حرارت - بیشتر قطعات تعویضکنندههای حرارتی از مس یا آلیاژهای آن ساخته شدهاند، به دلیل ظرفیت حرارتی بالا مس.

EN

EN AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

ET

ET

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

IS

IS

HY

HY

AZ

AZ

LA

LA

MN

MN

MY

MY

XH

XH